Building exterior cladding, using metals like steel, aluminum, copper, or stainless steel, is a key component for structural integrity and visual appeal, protecting buildings from environmental factors. The meticulous fabrication process combines advanced machinery with traditional craftsmanship to create diverse designs. Installation demands precision and best practices, including proper substrate preparation, alignment, sealing, and inspections, ensuring longevity and aesthetic appeal. Metal cladding's durability against extreme conditions, versatility in design, and sustainability make it a top choice for both residential and commercial projects.

In the realm of architectural aesthetics and structural durability, building exterior cladding plays a pivotal role. This article delves into the intricate world of exterior metal panel cladding, exploring its materials, fabrication techniques, and installation nuances. We dissect the art and science behind expert fabrication for metal panels, highlighting best practices that ensure superior performance. Additionally, we analyze current trends, benefits, and installation strategies in building exterior cladding using metal panels.

- Understanding Building Exterior Cladding: Materials and Options

- The Art of Expert Fabrication for Metal Panels

- Installation Techniques and Best Practices

- Benefits and Trends in Exterior Metal Panel Cladding

Understanding Building Exterior Cladding: Materials and Options

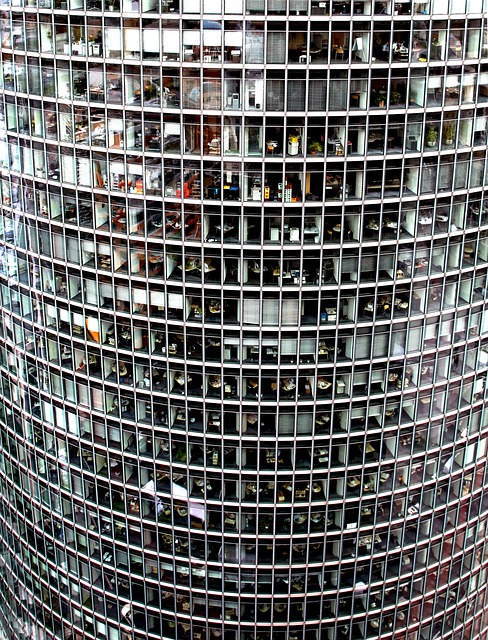

Building exterior cladding plays a vital role in defining a structure’s aesthetics and functionality. It serves as a protective barrier, shielding buildings from the elements while enhancing their visual appeal. When it comes to materials, there’s a diverse range of options available for exterior metal panels. These include various types of steel, aluminum, copper, and stainless steel, each offering unique properties in terms of durability, maintenance requirements, and design versatility.

For instance, steel cladding is renowned for its exceptional strength and longevity, often used in commercial buildings to withstand harsh weather conditions. On the other hand, aluminum offers lightweight protection with excellent corrosion resistance, making it a popular choice for residential applications. Copper and stainless steel add a touch of elegance, with copper providing natural aging aesthetics and stainless steel ensuring minimal maintenance and maximum durability. Understanding these materials is crucial when selecting appropriate building exterior cladding for any project.

The Art of Expert Fabrication for Metal Panels

The art of expert fabrication for metal panels is a intricate and precise process, vital to the transformation of raw materials into striking architectural features. Skilled artisans and engineers harness their expertise to craft exterior cladding that not only enhances structural integrity but also contributes to the visual appeal of any building. This involves meticulous cutting, forming, and joining techniques to create seamless, durable panels ready for installation.

By combining advanced machinery with traditional craftsmanship, experts are able to produce a diverse range of designs, from sleek, modern profiles to intricate, vintage-inspired patterns. These metal panels then become versatile building blocks, offering designers and architects endless possibilities for creating unique facades that stand the test of time. Whether adorning historic landmarks or contemporary skyscrapers, expert fabrication ensures exterior cladding that is both aesthetically captivating and structurally sound.

Installation Techniques and Best Practices

The installation of exterior metal panels is a critical step in the fabrication process, requiring precision and adherence to best practices to ensure the longevity and aesthetic appeal of building exterior cladding. One of the key considerations is choosing the appropriate installation method for the specific panel design and building structure. This may involve mechanical fastening, such as using screws or rivets, or applying adhesive bonds for a seamless finish. Proper preparation of the substrate is paramount; surfaces must be clean, dry, and free from contaminants to guarantee optimal adhesion.

Best practices include ensuring precise alignment of panels during installation to maintain uniform spacing and avoid gaps. Weatherproofing is essential to protect against environmental elements, so sealing joints and edges with appropriate seals or gaskets is recommended. Regular inspection throughout the installation process helps identify any issues early on, ensuring the final product meets high-quality standards for building exterior cladding.

Benefits and Trends in Exterior Metal Panel Cladding

Exterior metal panel cladding has gained significant popularity in the construction industry due to its diverse benefits. Firstly, it offers exceptional durability and resistance to various environmental factors such as extreme temperatures, moisture, and UV radiation. This makes metal panels a reliable choice for building exterior cladding, ensuring structures remain robust and visually appealing over extended periods. Moreover, these panels are highly versatile, available in numerous designs, finishes, and colors, allowing architects and designers to create unique aesthetics that cater to modern aesthetic preferences.

Trends in this sector highlight a growing emphasis on sustainability and innovation. Manufacturers are incorporating recycled materials into production processes, reducing the environmental impact of metal cladding. Additionally, advanced technologies enable precise cutting and forming of panels, resulting in intricate designs and seamless installations. This evolution not only enhances the visual appeal of buildings but also contributes to energy efficiency by providing excellent thermal insulation properties. As a result, exterior metal panel cladding is increasingly preferred for both residential and commercial projects, seeking to balance durability, aesthetics, and environmental considerations.

In the realm of building exterior cladding, metal panels have emerged as a versatile and durable option. The art of expert fabrication ensures these panels are meticulously crafted to withstand various environmental conditions, enhancing the aesthetic appeal and longevity of any structure. By understanding the materials, installation techniques, and current trends, architects and builders can leverage the benefits of exterior metal panel cladding, revolutionizing the way we construct vibrant, bustling metropolises.